News details

2019-12-24

[Professional knowledge] The structure and application selection of oil seals, very detailed oil seal training materials, is worth seeing

What is oil seal?

In a word, the so -called oil seal is a mechanical element that is composed of synthetic rubber, metal rings and springs to prevent lubricating oil from leaking from the machine gap. The mechanical element is used, also known as the rotating shaft lip -shaped sealing ring.

The mechanical rubbing part is used to prevent the use of oil from the gap between the mechanical gap during the mechanical operation. However, due to the development of mechanical technology, in addition to oil, it is necessary to prevent leakage of water and chemical liquids and the invasion of dust from the outside. At this time, oil sealing must be used.

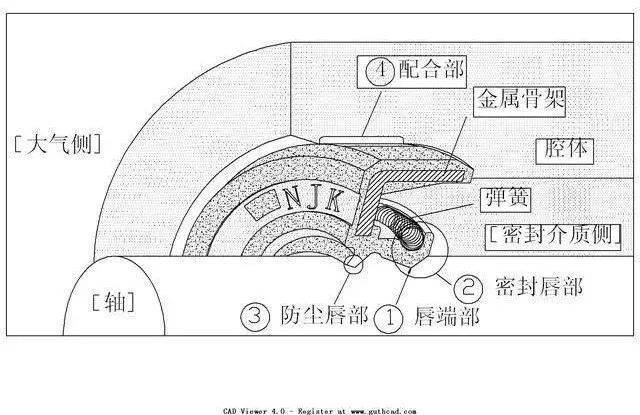

Names of all parts of oil seal

The role of all parts of oil seal

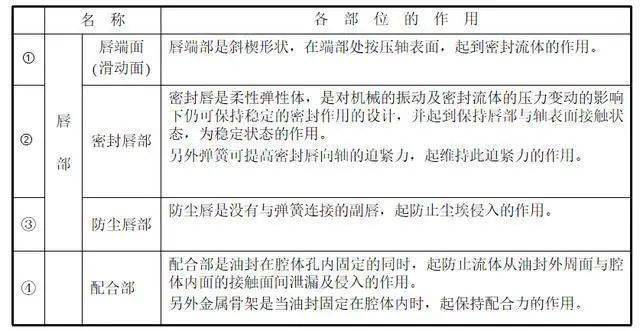

Common materials for oil seal

1. Main rubber types and specialties

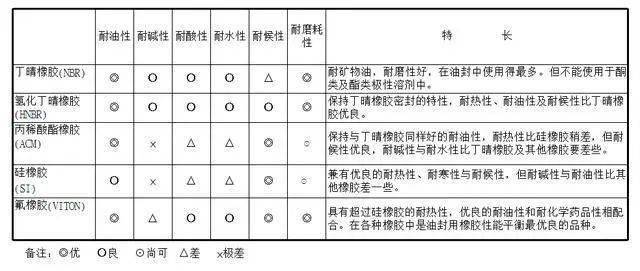

2.Second, NJK represents the type and main use of the lip material material

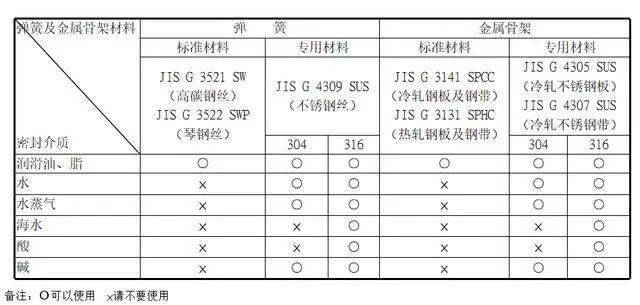

Spring, metal skeleton

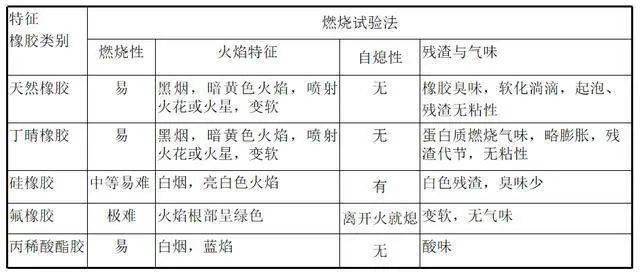

Oil seal rubber selection

This time, the focus of our discussion is "the allowable temperature range of oil seal"

In fact, the oil seal allows the temperature range (limit value) is determined by the characteristics of the lip mouth material, the type of sealing medium, the axis eccentricity, the time of use, and the speed at the time of starting. Here, we take the S -shaped oil seal as an example.

PS: Type t -sealing lips are twice ascending to S -type sealing lip temperature, while the V and K type are the same as the S type.

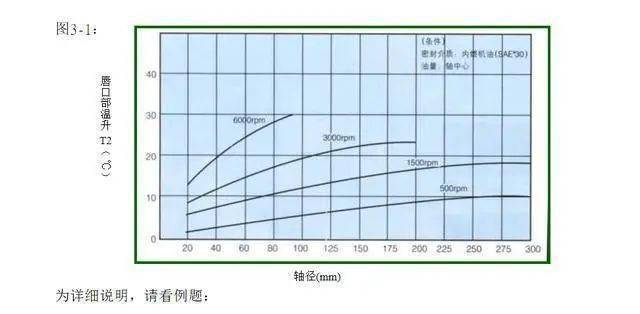

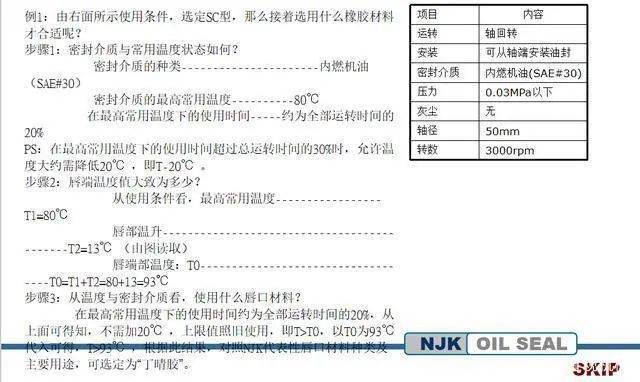

In order to choose the sealing lip material of the oil seal, the temperature (T0) at the end of the lip needs to be roughly preserved. The highest commonly used temperature (T1) and the highest commonly used temperature (T1) and the lip slide due to the axis and lips (refer to Figure 3-1) on the machine and device on the machine and device. formula.

That is: T0 = T1+T2

According to the temperature and sealing medium at the end of the lip, the lip material can be selected, but the allowable temperature of the lip mouth material can be changed due to the operating state of the machine.

PS: Using gear oil and high-viscosity silicon oil, the lip temperature rising T2 is 1.5 times that of Figure 3-1, and the temperature of the lower lip in the lower lip is 3 times.

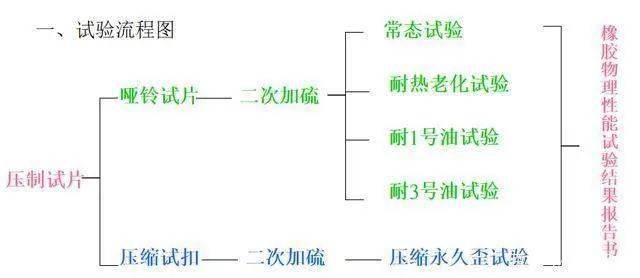

Rubber physical performance test

How to use the general oil seal:

No matter how suitable the design and selection of the installation of the oil seal, if the assembly is rough in use, it cannot exert the scheduled function. This chapter mainly introduces the correct use method when the assembly or replacement of the oil seal is introduced. Read carefully before using oil sealing and obey the precautions.

1. How to use njk standard oil sealing

The use of standard oil seals is described as follows:

1. Packing

The oil seal transported to your hand is different from the size and the number. Generally packaged in bags, rust paper, corrugated board boxes. Due to the prevention of rust, adhesion of foreign objects or damage, open seal before assembling.

2. Storage

When storing the storage oil seal, please pay attention to the following matters.

① Please do not open the packaging, because you are worried that you will adhere to dust and be damaged.

② Please do not be irradiated by sunlight for a long time. Ultraviolet rays can accelerate rubber.

③ Please do not place it in a humid place. The humid environment will make the outer circle around the metal oil seal and the oil seal equipped with a spring rust.

④ Please do not place near high temperature heat sources such as boilers and stoves, because thermal will promote rubber aging.

⑤ Please do not hang the oil seal with a thin rope and hang it on the nail or metal line, which will cause the oil seal deformation and damage of the lip end.

⑥ For oil seals that have been opened and unused, please prevent rust and prevent foreign objects such as sand and dust.

⑦ In order to prevent oil seal deformation and spring falling off when using and handling oil seals, please do not impact too much.

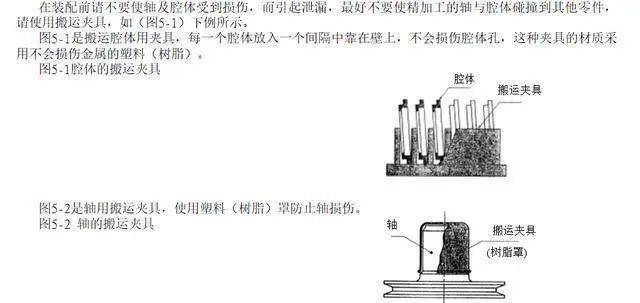

3. Protection of axis and cavity

4. Preparation before assembly

Oil seal

① When using the storage oil seal, please do not use oil seal with foreign objects such as sand and dust, which will cause leakage.

② Please do not rub the ends of the mouth of the lips with nails and hard objects. The end of the lip is the most important part of the oil seal function.

③ Type, K -shaped oil seal, etc. are oil seals with more than 2 lips. Fill the lubricant to fill the fat, fill the lithium lithium lubricating fat between the lips and lubricate the lip of the mouth.

④ The oil seal such as S type, V, and TCK only has one lip mouth. Please apply lubricating fat at the end of the lip at the ends of the lip to lubricate the lip mouth.

Axis, cavity

① The axis surface and the inside of the cavity hole are confirmed that there must be foreign objects such as anti -rust oil or sand dust. If it is attached, please wash it. When washed with washing oil and gasoline, wipe it clean.

At this time, the compressed air is sprayed, which can make the invisible parts be cleaned. Washing oil and gasoline remain in the axis and cavity holes, which will swell the oil seal and fail.

② When the inner surface of the cavity hole and the chamfer part and the oil seal should not have burrs and defects when passing through the axis end and axis. Because the burrs and defects will become the cause of the lips and the outer peripheral damage during installation, please remove it with diamond sandpaper.

③ Please confirm that there is no defect and rust when the surface of the lip is in contact with the axis surface. The defects and rust on the axis surface are the direct causes of leakage.

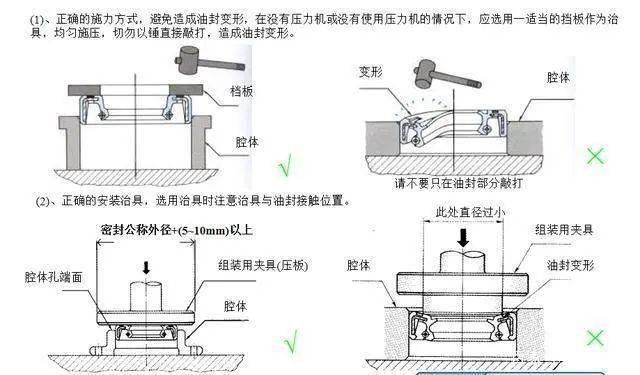

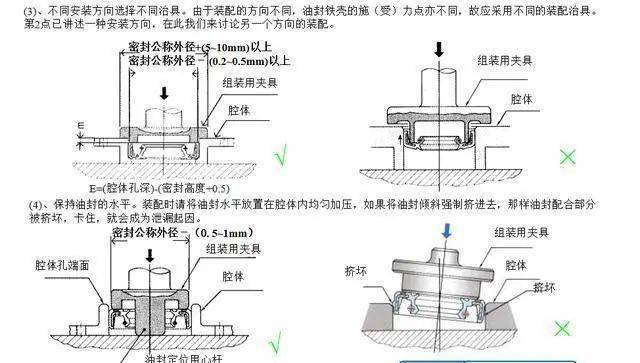

5. Installation to the cavity hole

The success or failure of the installation relationship of the oil seal, the excellent oil seal design will not be able to play the effect of the seal if there is no correct assembly, so the correct assembly treatment must be used and the correct installation steps must be used to install.

Before the installation, the oil seal must be lubricated in advance with oil or fat to reduce the contact surface when the installation is touched and friction. At the same time, it can also prevent the initial rotating oil seal from damaging the poor lubrication.

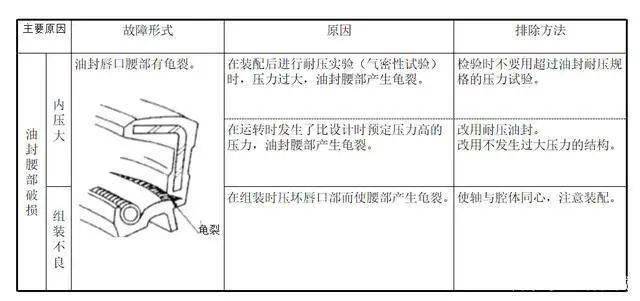

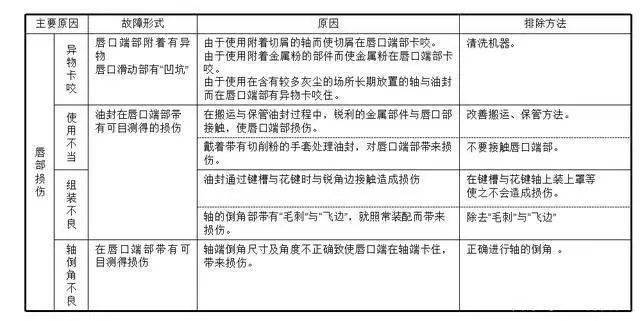

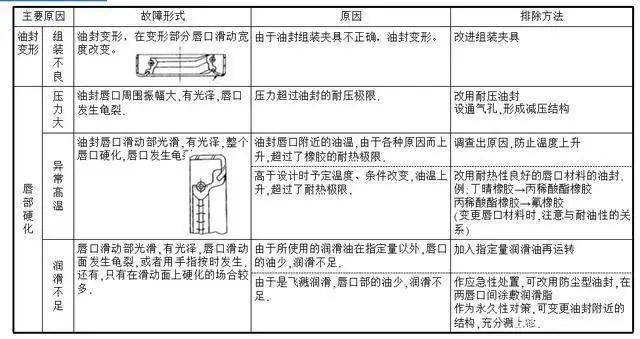

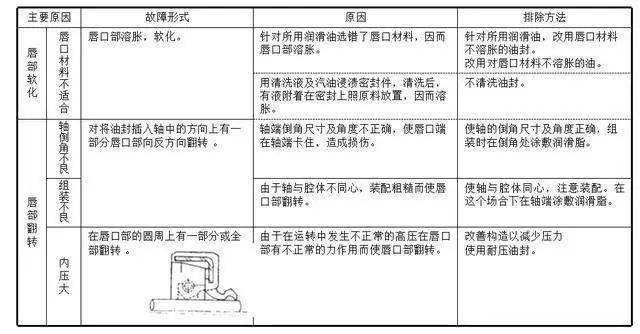

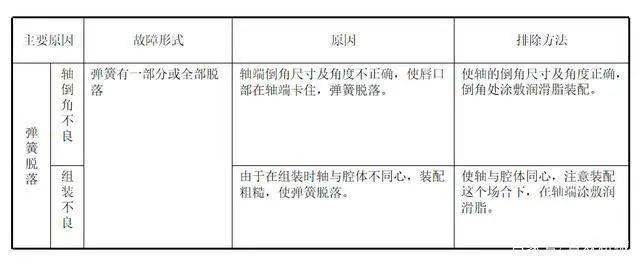

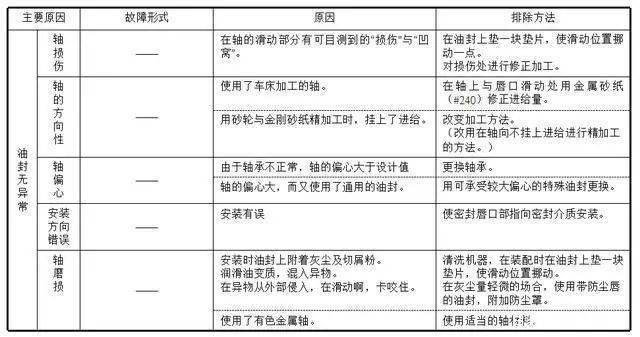

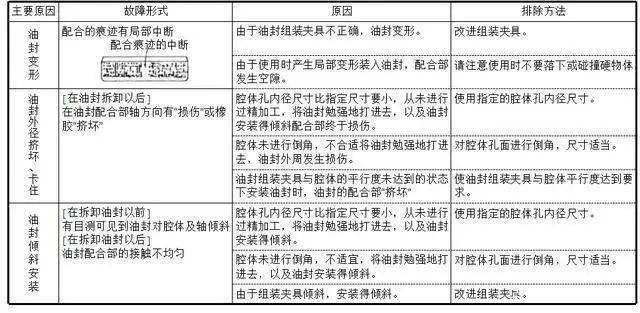

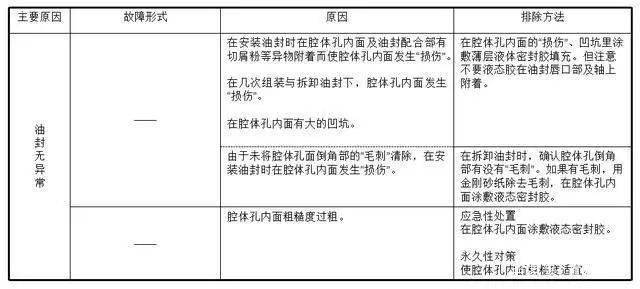

The main points of inspection when the oil seal occurred

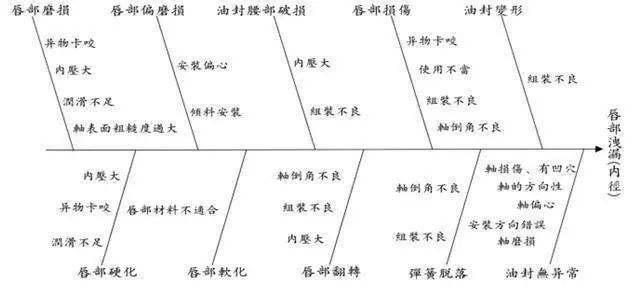

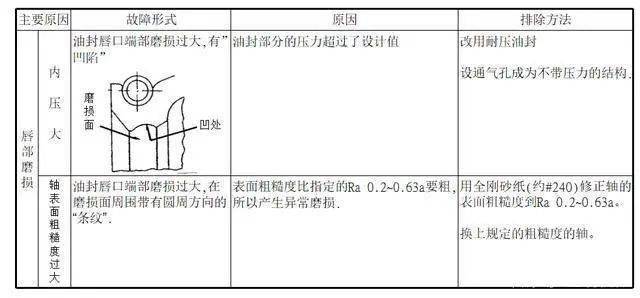

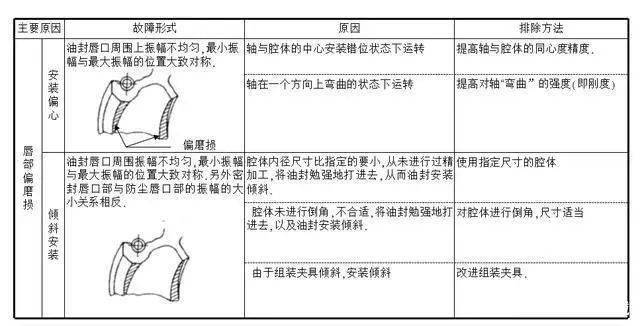

1. The main reason for leaking from the lip mouth

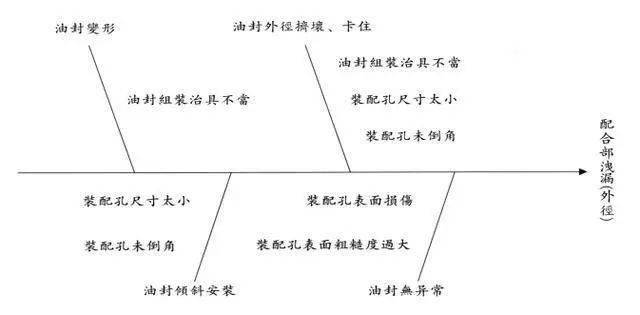

2. The main reasons for leaking by the cooperation department

3. Leak from the lip mouth (inner diameter)

4. outer diameter leak (outer diameter)

Disclaimer: This article is reproduced by the network, and the copyright belongs to the original author. If it involves copyright, please contact delete! The content of the article only represents the author's personal point of view, and reprints the same views different from this platform's identity or holding the same view.

Language: CH

Language: CH

Leave a Comment